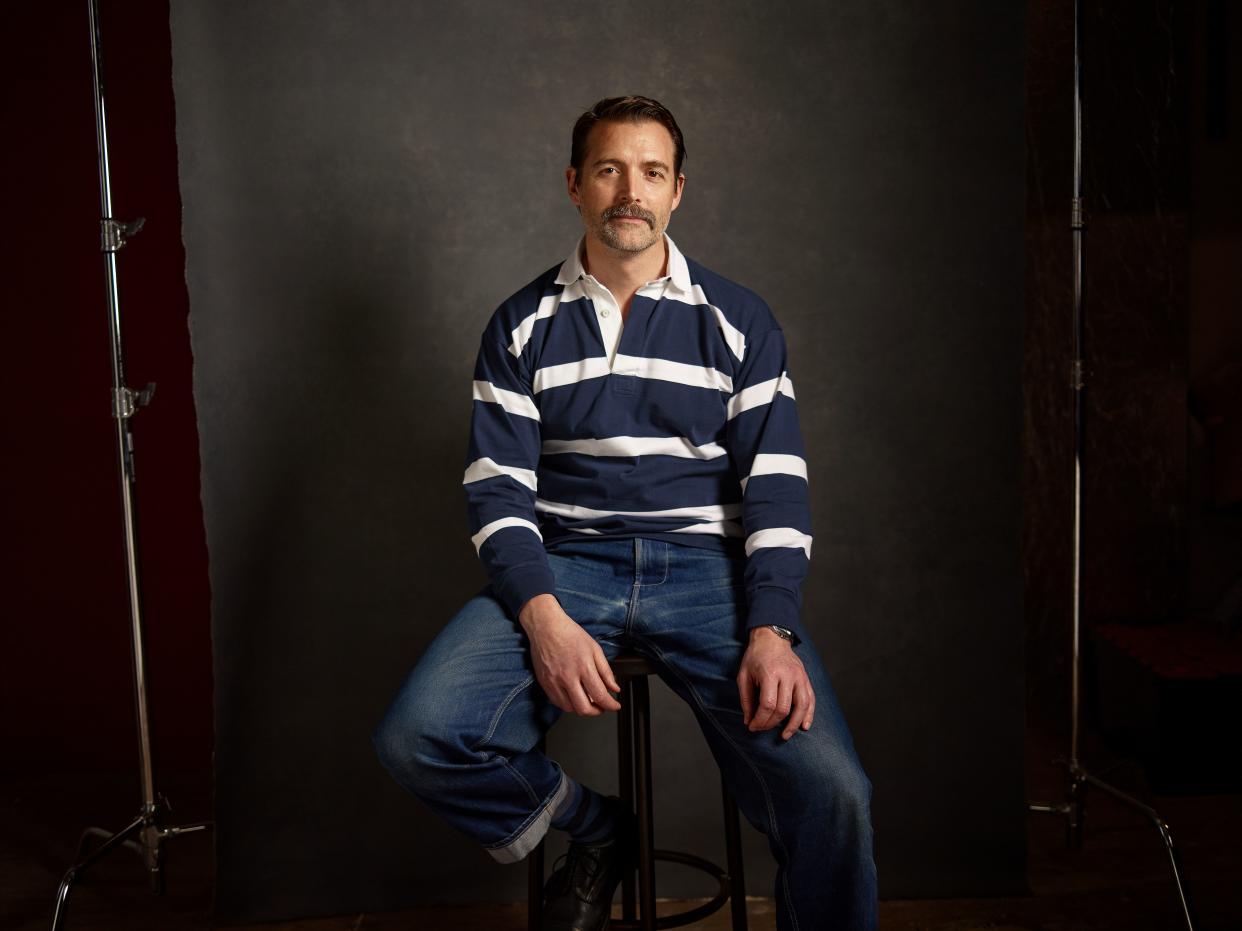

Community Clothing founder: 'The UK high street offering is cheap garbage'

Patrick Grant adheres to the slogan coined by the founder of Molson Canadian, who once said “an honest beer makes its own friends.” Grant, who set up Community Clothing in 2016, says: “That’s our philosophy too.”

Blackburn-based Community Clothing is a fast-growing business, eschewing fast fashion for quality manufacturing and keeping the British textile industry firmly alive. Word of mouth is key too, with their marketing spend (£200 or so on Google ads in the week that we speak) next to nothing.

Not so long ago, says Grant, the textile industry in the UK supported 1.6 million jobs, today it’s less than 100,000. In setting up Community Clothing, Grant’s company vision was two-fold: to create and sustain jobs and make high quality, affordable, long-lasting clothes.

Read More: 'We turned down Dragons' Den offers - our eyecare company is worth £7m now'

“If you are an ordinary Joe today and you go to the British high street to buy clothing ... it’s garbage," says Grant, who is also a judge on BBC’s The Great British Sewing Bee. “The socks, pants and jumpers are abysmal quality and made out of the thinnest material in the cheapest possible way.

“Everybody else has chipped away at the quality of clothing over a 50-year period. We are against that philosophy. Our product is the same, we don’t waste anything and try to standardise as much as possible.”

The seeds have been sown from Grant’s near 30-year professional career, which started in engineering, in 1995, at a blue-chip British manufacturing business called BICC. Back then there were five factories across the North West, with BICC employing 35,000 staff, most of them in manufacturing roles.

In 2005, a move into the textiles industry saw Grant, a former under-19 Scotland rugby player, revive the 200-year-old tailoring house Norton & Sons on Savile Row, where he sourced fine cloths from some of Britain’s mills who he now works with today. It was here that Grant understood the value of creating a story and actually meeting the tailors. “Those connections make those suits feel special to the customers,” he says.

Four years later he relaunched British designer brand E. Tautz and was awarded Menswear Designer of the Year at the 2010 British Fashion Awards. In 2015 he then took over 160-year-old clothing manufacturer Cookson & Clegg and saved it from closure.

The move came after an email he received one Sunday. The following day he wrote to the CEO and took on the business. “Looking at the books you understand how so many manufacturing businesses in the UK are failing,” he recalls. “They don’t have big enough orders, it’s seasonal business. They were making a painstakingly good product but it was expensive.

"A British made raincoat might start at £600 but a raincoat at Debenhams was selling for £120. That was a big jump which people weren’t prepared to make, even with the knowledge that they would be supporting local jobs.”

First launched on eBay eight years ago, Community Clothing — “we are a clothing, not a fashion business,” says Grant — ensures that 65% is paid to the skilled manufacturers, as opposed to the normal model of around 22% of consumer spend.

Waste is clearly key for Grant. Indeed, there is no seasonal fashion when it comes to Community Clothing’s output. Why are we changing the pockets and collar on this raincoat when everybody likes it as it is, was Grant’s argument to retailers.

While Grant writes the emails and copy for the website, the social enterprise firm’s marketing budget (five percent) pales in comparison with other social media heavy fashion outlets.

Read More: Meet vertical farm GrowUp, the UK’s fastest-growing salad brand

What they shoot will normally be in Blackburn. A sunny Lancashire day for content creation is clearly a blessing. “The product speaks for itself," admits Grant, "and once people try our product they will keep buying it."

Grant read with interest how fast fashion behemoth Shein turned over $1 billion in the UK last year and forecast to become one of the top 10 apparel firms in the country. Meanwhile UK factories were, says Grant, being “hollowed out by offshoring”.

He adds: “Our view is to encourage people to buy more carefully, buy products which will last. The great irony is that the cheaper the clothes the more likely the money will end up in the pockets of a billionaire sitting on a yacht.

“I grew up with good clothes, leather shoes which took five years to get comfortable in or wool overcoats that took time to mold to your body and once you got it right you wouldn’t want to be parted from it. It meant something.

“Now you can buy a top for less than a cup of coffee. People are being paid peanuts for making these clothes. It’s everything that’s wrong with the system and so we are offering a different way forward. Have fewer and better things and make them in a way that does good for a community.”

Community Clothing works with nearly 50 factories (14 within an hour of Grant’s base), predominantly in the old textile heartlands of Yorkshire, Lancashire, East Midlands and southern Scotland. There are also factories in Wales, north London and Sussex.

Grant regularly sees yarn spinners, dyers, weavers, jersey knitters or manufacturers at the home of the trainer, in Bolton, while during our interview at Grant's company headquarters, the factory bell goes off for morning break.

“We know how many people we work with who are employed (under 2,000), we know how many hours we have created (354,000 hours). We have thrown these factories a lifeline,” says Grant, who is decked out in Community’s socks, pants, trousers, T-shirt and a jumper.

Read More: Moss CEO on heritage brand rise and customer letters

Comfortable in his brand, he's enthusiastic about the future. With 12 staff, half of whom are part-time, Community Clothing has a near £3m turnover, with 60,000 customers and “fast growth”.

“We have reached only a small number of people in the UK,” he adds. “But if we can get more switched on to good versus bad quality, it will be better for the planet and the customers.

“Our ambition is to create 5,000 permanent skilled jobs in our sector. What we’ve done is just redistributed the money and you’ve got to think differently. It all boils down to making something good and almost everybody else has forgotten about that. It feels like an opportunity to me.”

Watch: Woman creates new fashion trend for celebs following life changing car crash

Download the Yahoo Finance app, available for Apple and Android.